A condition monitoring system that can detect gear motor failures in advance!

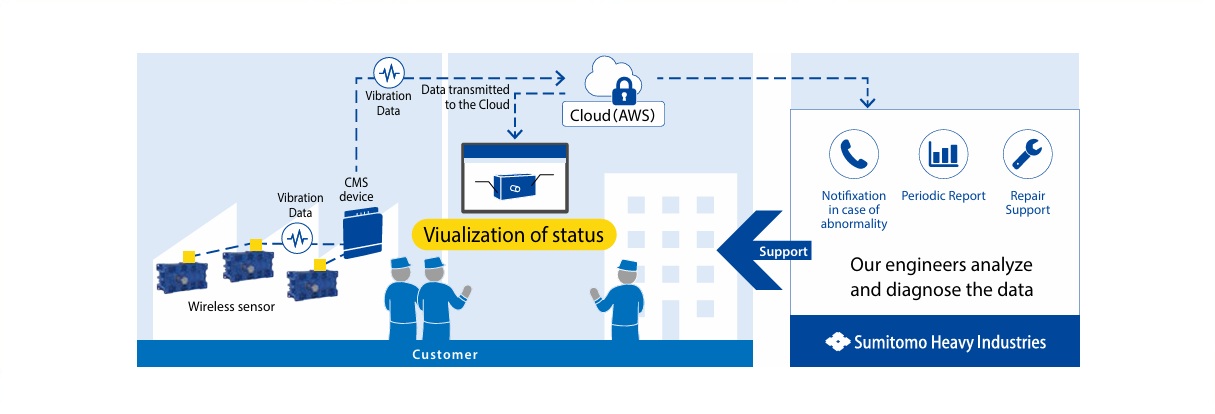

CMS is"Condition Monitoring System"

By monitoring the condition of the client's equipment, this system can detect signs of potential failures to prevent long-term downtime, and conversely, by understanding when the equipment is operating well, it can help reduce unnecessary maintenance.

■Failure detection is possible through vibration monitoring of the gear motor

Judge of abnormal vibration in a gear motor

■By managing the vibration trends of gear motors, it is possible to predict maintenance timing.

Reducing production line downtime through preventive maintenance

■Enables condition monitoring of gear motors installed in high places or high-temperature environments

Improving inspection efficiency through continuous monitoring (vibration) of gear motors

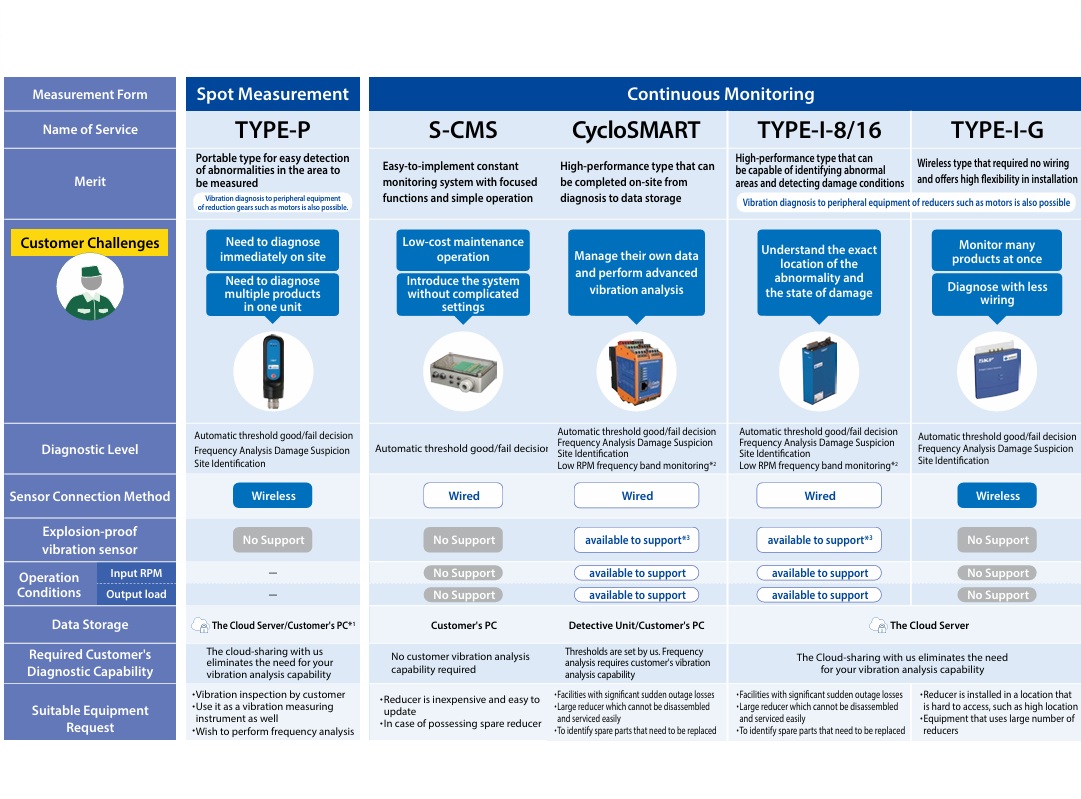

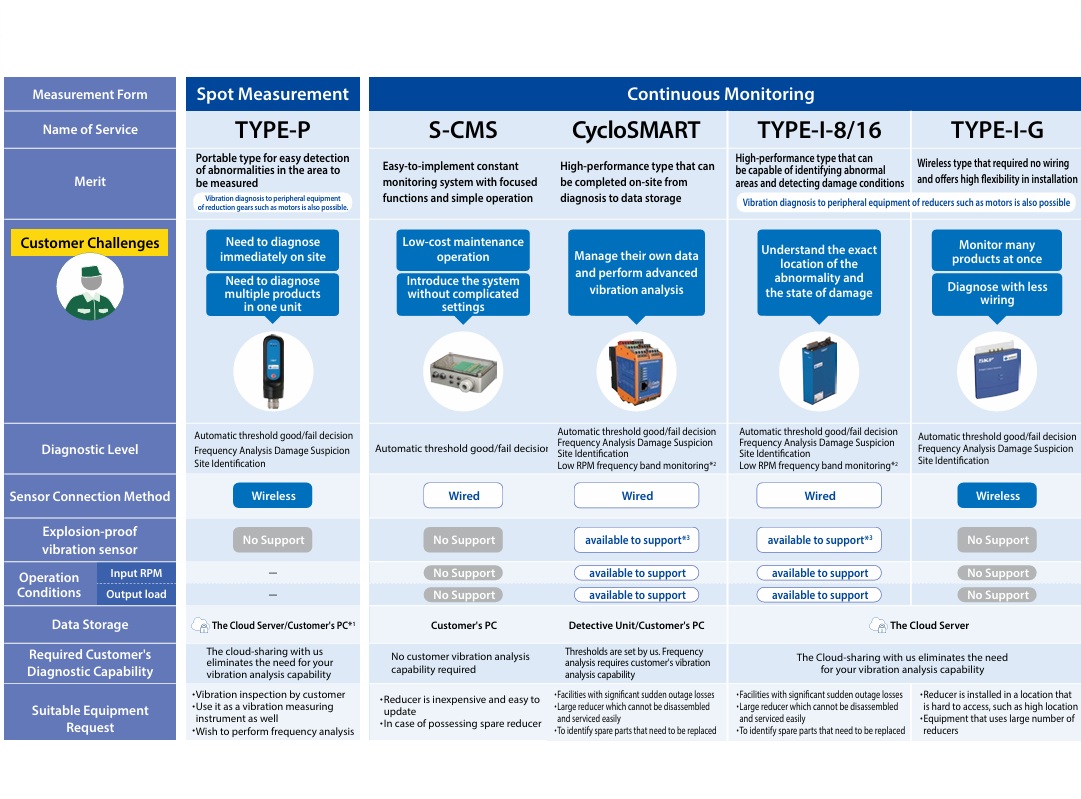

Condition Monitoring by POTABLE Sensor

Type-P

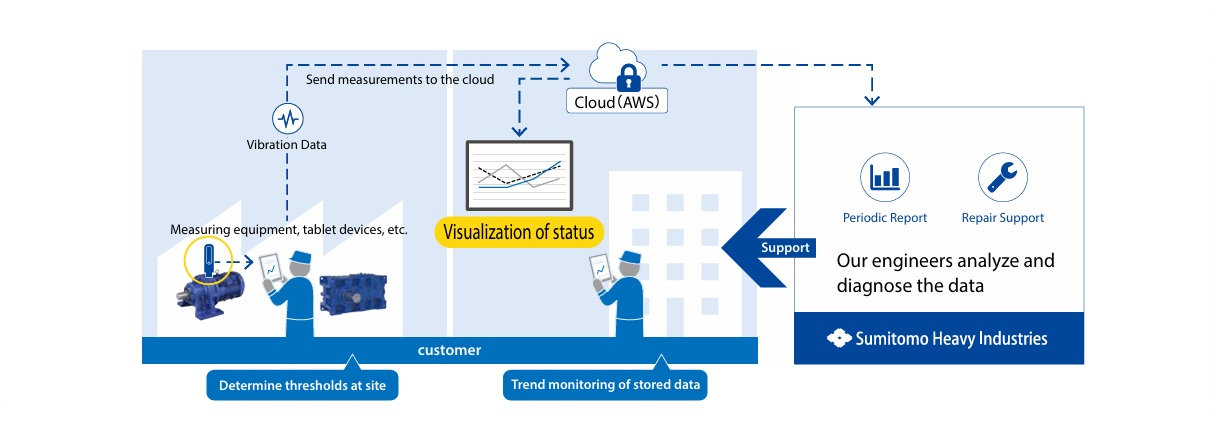

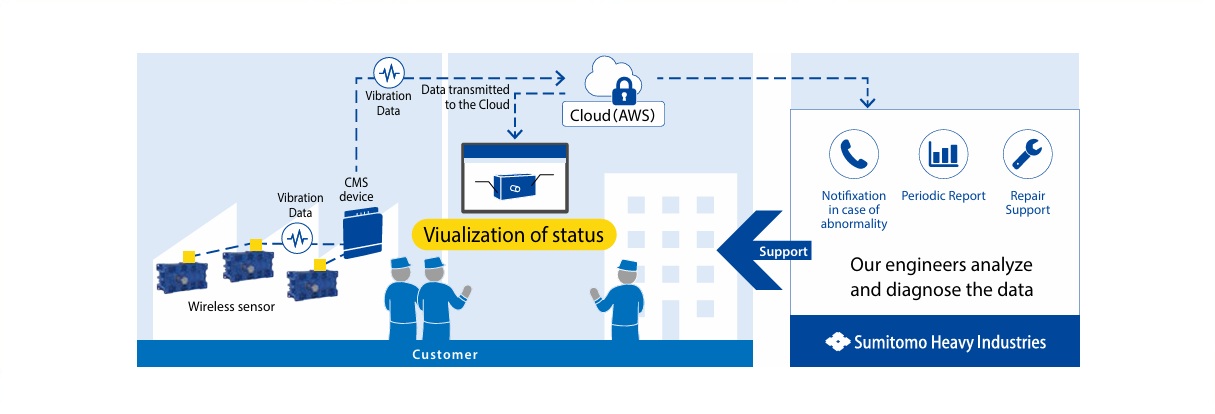

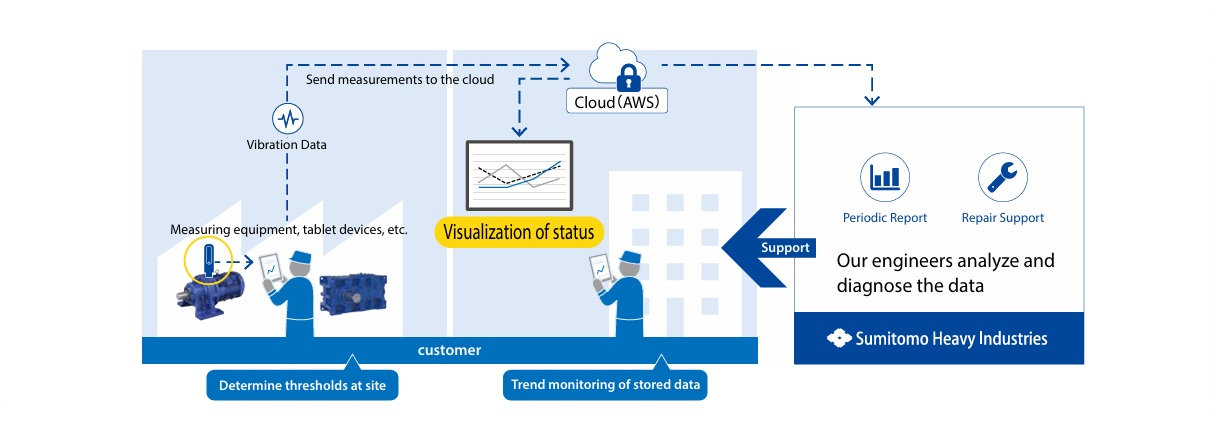

Condition Monitoring by SHI Specialist by Using Cloud Server

TYPE-I-G

- We can propose in various combinations to suit client's maintenance policies and budget.

NAGAKE ELECTRONICS

長宅電業株式会社

1795 Nakanoshima, Wakayama city, 640-8392

TEL: 073-422-1324

FAX: 073-428-3203

Any consultations of rotating machinery

Please contact fromHERE

We will propose the best option